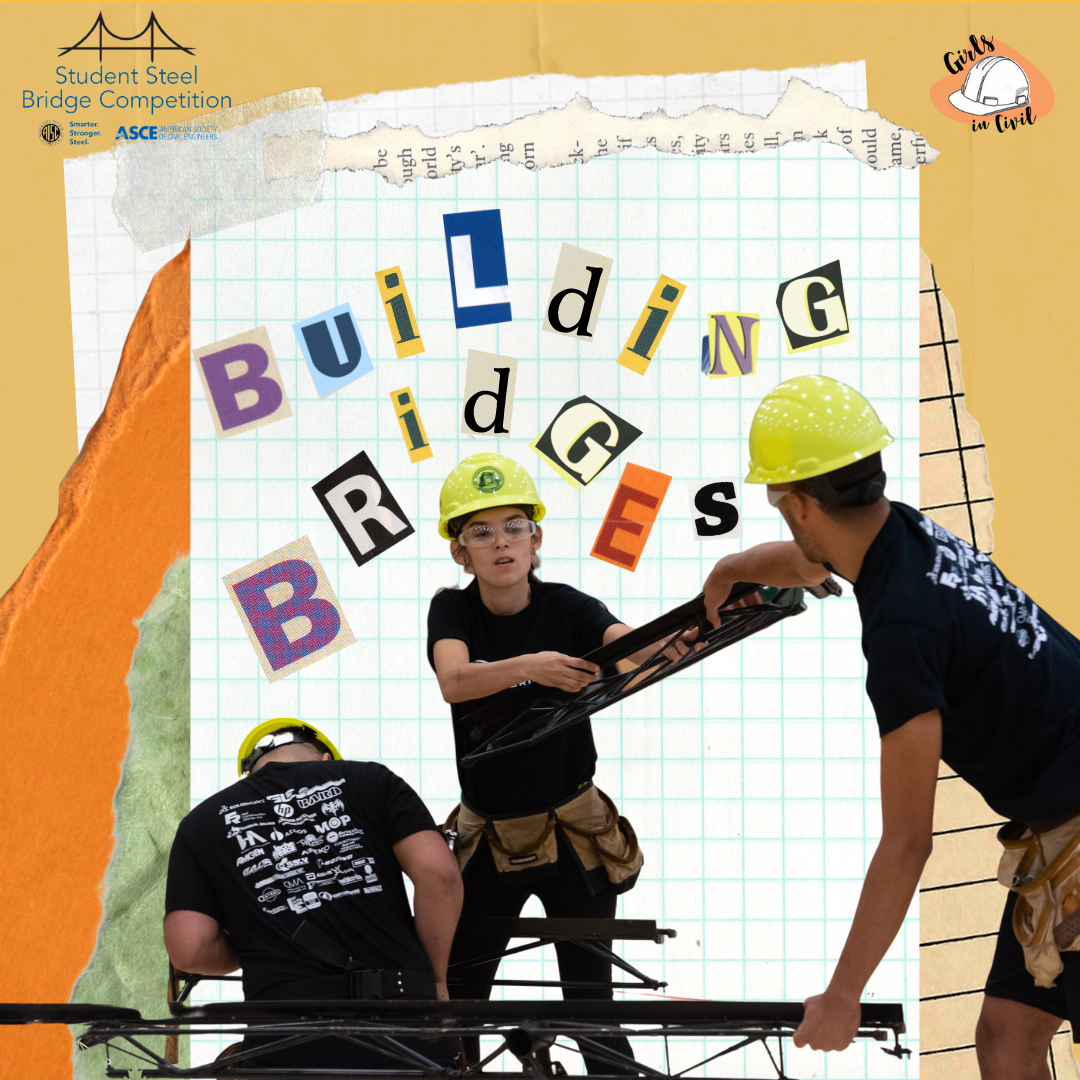

Building Bridges

Note: All experiences in this article are written by Sofia, Gilmarie, Gabriela, and Charmelis, past Team members from the UPRM Steel Bridge Team years: 2017-2018, 2018-2019, 2019-2020. All teams around the nation have different practices and experiences. Our goal is to share our lessons learned in hopes of helping students that are interested in the Steel Bridge Competitions.

Well, to be specific… Building small bridges!

Let's talk about building a 20 feet long, 5 feet tall, and 3 feet wide steel bridge for university competitions.

Sounds peculiar, right?

Did you know four of our team members were part of the Steel Bridge Team?

Fun fact, that's how they met! Building Bridges for two years.

In this blog article, we are finally taking the time to share our journey into the steel bridge world. Our goal is simple: to share our experiences and hopefully help you find undergrad experiences that make you develop soft and technical skills. But also a love for the Civil Engineering Universe.

Today we are starting with our Steel Bridge Team experiences. We will continue to share more undergrad experiences in the upcoming months.

So, let's start with the most straightforward question, what is the AISC Student Steel Bridge Competition?

The mission of the American Institute of Steel Construction (AISC) Student Steel Bridge Competition (SSBC) is to supplement the education of civil engineering students with a comprehensive, student-driven project experience from conception and design through manufacturing, construction, and testing, culminating in a steel structure that meets client specifications and optimizes performance and economy. The SSBC increases awareness of real-world engineering issues such as spatial constraints, material properties, strength, serviceability, fabrication, erection processes, safety, aesthetics, and cost. Success in intercollegiate competition requires effective teamwork and project management. Future engineers are encouraged to innovate, practice professionalism, and use structural steel efficiently.

In the event, the bridge is evaluated in seven categories: lightness, stiffness, structural efficiency, construction speed, economy, cost estimate, and aesthetics. In other words, the structure must be as light as possible and assembled as fast as possible, and then support approximately 2,600 pounds with deflecting as little as possible. These categories are translated as a cost using formulas provided in the competition rules. As in a real-life construction auction, the bridge with the least total cost wins the competition.

There are also special awards that recognize the extraordinary achievements of teams in addition to the competition category awards. These awards include the following:

SSBC Team Engagement Award: presented to a team that demonstrates an outstanding commitment to building a diverse team, creating an inclusive environment, and appreciating the value of remarkable individuals working together to succeed. The basis for this competition is a one- to two-page written narrative detailing how the Team benefited from its efforts toward equity and diversity during recruiting, training, and working together to design and create the best bridge they can.

Robert E. Shaw, Jr. Spirit of the Competition Award: presented to a team that demonstrates outstanding team camaraderie, professionalism, positive work ethic, and respect for their competition peers.

Frank J. Hatfield Ingenuity Award: presented to a team that shows the most engineering ingenuity in the design and/or construction of their bridge based on the requirements of the competition rules.

Little background information:

Robert E. Shaw, Jr., founded the AISC Student Steel Bridge Competition in the spring of 1986 to challenge university and college students to use their engineering skills. Every competition we've gone to, he can be seen with a big smile and photographing all the bridges and teams!

Frank J. Hatfield was the Chair of the Student Steel Bridge Competition Rules Committee during its first three decades. He was responsible for orchestrating the many evolutions of the rules since the first Student Steel Bridge Competition in 1992 and was involved in the competition from its inception.

So, how does it get built? Let's go behind the scenes!

Students design and fabricate the bridge ultimately themselves. And over the course of a year, team members learn how to use structural analysis and design programs like SolidWorks, SAP 2000, and AutoCAD; they also learn how to use tools and how to weld.

They also learn to manage their time, work with a large team, and communicate with companies, professionals, and machine shops. With this being able to fund the project and get the materials they need to make it all possible.

The simplest way to explain this is by diving into phases:

Training (Summer months): Old members teach the new members how to use the different tools and programs using the old rules and the already built bridges to make the learning experience more visual and practical.

Design: Once the rules arrive (usually end of August or the start of September), we start designing! This process takes a lot of meeting hours and trial and error. Team members take what they learned in the summer months and develop solutions that work for the structure, considering all the constraints. Designs get eliminated until the final design is selected, and then there's a period of optimization, assuring the final design is constructible and optimum.

Pre-construction: This phase starts when the final design is about to be chosen, team members begin creating budget analyses, cost estimations, and looking for quotations from machine shops, steel suppliers, and hardware stores. Team members also start preparing the structures laboratory for work. The idea is to get ready before the steel pipes arrive. This way, no time is wasted. Since our Team is from Puerto Rico, materials took about 1-2 months to arrive on the island, so this phase was critical in determining the rest of the project schedule.

Construction: In November (or near that date), materials started arriving, and the fabrication of connections and steel cutting and welding commenced. This phase could last two months or more, depending on how easy or difficult the bridge was to construct.

5. Assembly: By February, we could see a complete bridge, which is where the dancing starts! And by dancing, we mean the assembly of the bridge. How fast and effectively could this structure be assembled? This all depends on the speed of your builders, the choreography that works best for the Team, and how well everybody communicates when changes are happening. It truly is a dance! This is the most exciting part of the competitions; everybody sees the builders perform, and you get to see some impressive teams.

6. Competition: This consists of getting your bridge to your Regionals competition destination (the date depends on your Region), and if you qualify for the National Finals (end of May or start of June), continuing the project for that other competition. This usually means optimizing the construction time or your bridge's structure. Some teams prepare for three competitions because they also get the opportunity to compete in Canada.

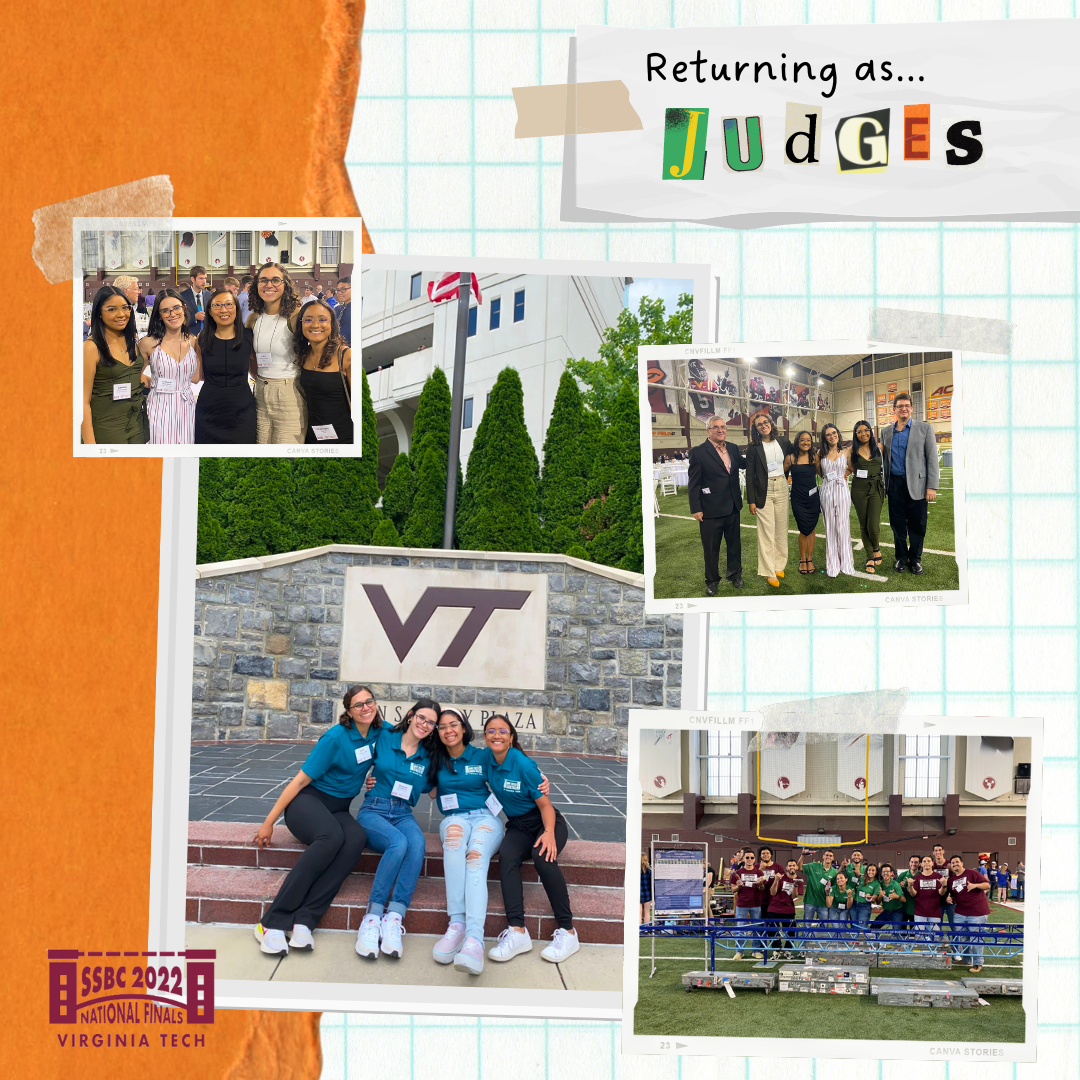

Returning to the Competitions as Judges

One of our directive members (Gabriela) had the following crazy idea this year:

"Hey, let's apply to volunteer for the National Finals SSBC. It's on my birthday weekend, so please say yes."

And the rest of us were like:

"Okay?! Let's sign up!"

We thought many times that this would never happen, but guess what? It did! We went back to the competitions as Volunteers, and when we got there, we realized that all of us would be judging different categories of the competitions.

How did we felt? Flabbergasted! The whole experience felt incredible. Seeing it from the other side made us realize how much we learned in these competitions, and we are incredibly grateful for all of it. It brought a sense of nostalgia but, at the same time, helped close an important chapter of our university experience.

It was a great experience exploring the other side of the competitions. Knowing how much students put into their designs and being there to see how it goes for them. Hoping that we didn't have to be the "bad guys" and telling them that something went wrong. Also, being able to share old experiences with other judges that came back just like us and even having young women reach out to know how we did it and where we are now.

Come to think of it, if bridges are meant to connect us from one point to the other… In the end… we did build BIG bridges full of opportunities and connections to new experiences and challenges that have helped us grow and continue developing our skills as Civil Engineers but, most importantly, as community members.

Lessons Learned!

Joining a competition team is one of the best ways to get introduced to Civil Engineering because you can see all the concepts you are learning in class.

Trust your team members' capabilities, professors, and sponsors' advice. They are all in this together. They all want to do their best in the competitions.

We developed leadership and teamwork skills. It was not only one or two ideas for design; it was twenty-plus ideas that had to come together into one final product. We had to listen, learn, and support each other even though we didn't always agree on everything.

Learned to design and consider how to take the bridge design to real life. Considering human building errors, possible material problems, the bridge's shipping, and limited budget and time.

We went to competitions where we met students from different locations. This was great because we all exchanged experiences designing, building, and constructing the bridge.

Companies like this type of competition because we all develop good leadership and technical skills, such as problem-solving, time management, teamwork, public speaking, computer programs, and quick thinking.

Learned about resiliency and how we can make a lot with a little. All these other universities have much more resources and equipment; however, we were always able to rise to their level by being creative, working hard, and operating as a team.

Quick Facts!

One year-long project, and rules for the bridge design change every year

The competitions are open to undergraduates and graduates of any major! We've had team members from Civil Engineering Department, Mechanical Engineering Department, Industrial Engineering, and Business Administration. The project has many parts, like engineering, construction, marketing, and outreach, thus making the project perfect for any major to join in and help the teams evolve and improve each year.

Students extend their classroom knowledge to a practical and hands-on steel-design project. You don't have to know any special skills to be part of a Steel Bridge Team; you'll learn a lot along the way. So, it would be best if you stayed open to learning.

All year long, you are doing research-related activities. Examples: Research on innovative and cost-effective steel bridge design techniques or research on initiatives for marketing for sponsorships

Students learn to machine, weld, and fabricate steel sections and connection components using steel as a bridge construction material.

Develop an understanding and appreciation of the engineering capabilities of steel as a bridge-building material

Teams are engaged in a hands-on learning experience that mimics "real-world" scenarios.

You get to travel to new locations and have the opportunity to grow your network of people in the industry. AISC steel bridge competition develops students' interpersonal and professional skills, encourages innovation, and fosters impactful relationships with other university students and industry professionals.